Tanaruz plans to produce 300 3D printed boats by 2023

Manufacturer of customizable 3D printed boats Tanaruz is would have plans to increase production of its commercial boats to 300 by 2023.

3D printed using reusable polymers, the boats are said to be more durable and cheaper to produce than conventionally made models, and come in a range of four models ranging in length from 4.5 to 10 meters.

Improving sustainability with 3D printing

Tanaruz’s boats are manufactured in its Rotterdam factory using a 14-meter-long 3D printer and are designed to embody the principles of a circular economy. All of the company‘s boats are made from reclaimed and recycled polymers which, at the end of a boat’s life, can be shredded and reused to print a new boat.

According to Tanaruz, this means that the production of its boats results in zero material costs and waste. In particular, the boats are printed with reclaimed polypropylene containing 30% fiberglass to provide desirable mechanical properties such as resistance to elongated deformation up to 5%, as well as resistance to heat, fire and to chemicals.

Other eco-friendly additions include electric motors to power the boats and the ability to mount solar panels to generate renewable energy.

A custom boat 3D printer

Traditional methods of manufacturing yachts and pleasure boats tend to require a lot of manual labor, which makes them expensive and often time-consuming to produce.

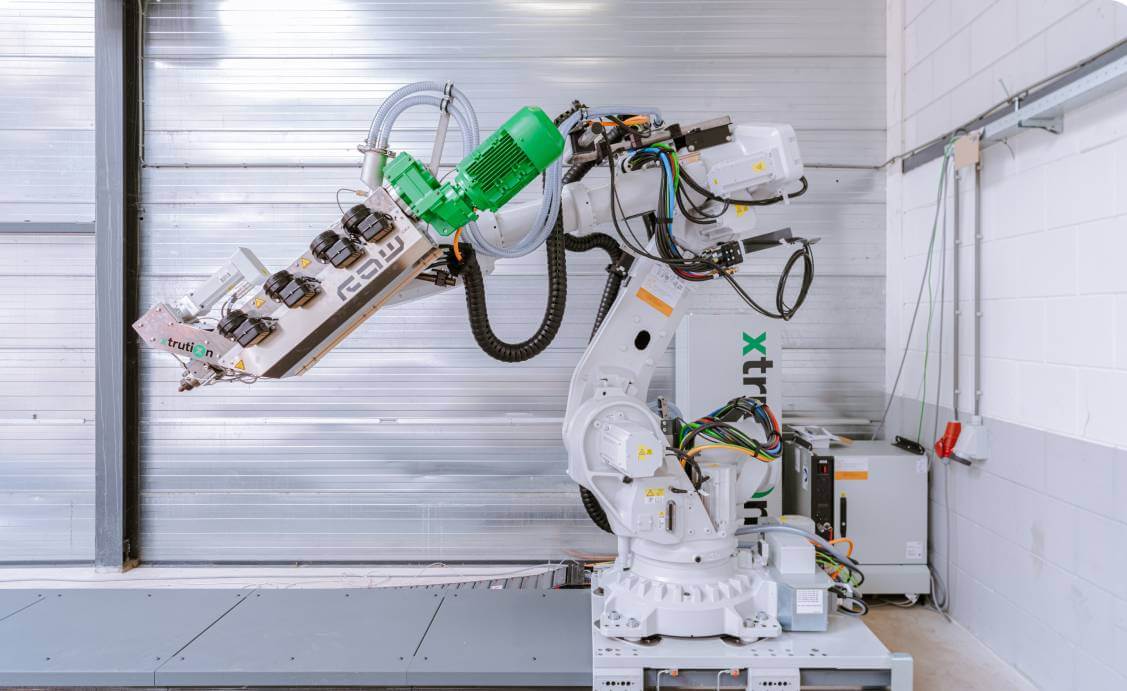

To manufacture its boats, Tanaruz deploys a 3D printer specially designed by the Swiss-Swedish multinational electrical equipment ABB. The company’s Track Motion robotic system is said to be the only track on the market offering high speed, precision and flexibility, and has been optimized with the ideal settings to robotically 3D print Tanaruz’s various boats.

The 3D printer also has an extruder made by a Dutch company Xtrusionwhich manages the process of melting and extruding recovered polymers according to Tanaruz specifications.

According to the company, 3D printing technology facilitates the smart and efficient production of its boats through more precise control and shorter production times, while minimizing waste during the construction process. The technology also stimulates creativity and flexibility throughout the production process, in line with circular economy processes and the reduction of Tanaruz’s impact on the environment.

Increase production

Tanaruz currently produces four models of boats, ranging from 4.5 meters in length up to 10 meters. The boats can be customized and equipped with electric motors, batteries and solar panels, while customers can choose the color, interior and equipment of their vessel.

Along with the durability and production cost benefits of 3D printing to build its boats, the technology also allows Tanaruz to lower the price of its yachts for its customers. The company’s entry-level model is priced at around €15,000, which, while still not affordable for many, could still be reduced as the company ramps up production.

This year, the company aims to 3D print around 100 pleasure yachts and aims to increase that number to 300 boats by 2023. The yachts are produced at the company’s Rotterdam factory, and plans are currently underway. in progress to find and open a second location to install more 3D printers to increase production.

With the addition of the new facility, Tanaruz says two printers could operate on a boat at the same time, potentially allowing boats over 10 meters to be 3D printed.

Going forward, the company is seeking partners and investors to expand its international reach, offering shipyards and print shops around the world the opportunity to get started with its plug-and-play additive manufacturing technology.

3D print ocean-going vessels

Tanaruz is not the only player making progress in the deployment of 3D printing for pleasure boats and yachts. Just last month, the University of Maine (UMaine) has 3D printed two new large-scale boats, one of which is said to be the largest ship ever additively manufactured. The ships were developed for the United States Marine Corps as logistic support ships, and will be tested for field use by the armed forces.

In fact, UMaine broke its own record for the largest 3D printed boat in the world, which until the unveiling of its new boats was its 3Dirigo model, measuring 25 feet long and printed in just 72 hours. Elsewhere, tech start-ups Composites Me showcased what it claimed was the world’s first 3D-printed boat in a continuous fiberglass thermoset material at the 2020 Genoa Boat Show.

Subscribe to the 3D Printing Industry Bulletin for the latest additive manufacturing news. You can also stay connected by following us on Twitter and love us on Facebook.

Looking for a career in additive manufacturing? To visit 3D printing works for a selection of roles in the industry.

Subscribe to our Youtube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows The 3D printed yacht of the DSI model of Tanaruz. Image via Tanaruz.

Comments are closed.