Redefining Traditional Material Transfer Vehicle Technology: CEG

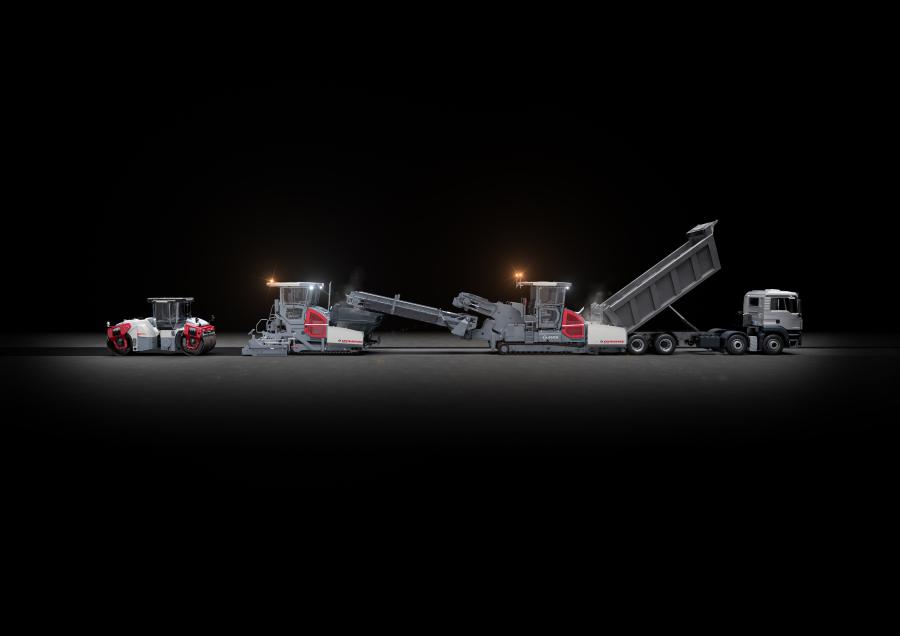

Dynapac presented its MF2500CS feeder compatible with iMIX technology at the The world of asphalt salon.

The IMIX system made its debut on Dynapac’s MF2500CS mobile loader, featuring a versatile belt system, intelligent operator assistance systems and flexibility to configure the machine for the right application.

IMIX Technology

Segregation of materials on a jobsite can occur during loading from the factory, transportation and dumping into the loader. Larger materials tend to move towards the outer sections, while smaller materials settle in the middle of the material flow.

The heart of the IMIX system is the combination of three strategically positioned devices: a conical auger in the hopper, a flow divider in the conveyor and a mixing system at the end of the main conveyor.

The augers in the hopper push the large particles, which stagnate in the cooler outer sections of the hopper towards the middle of the conveyor to join the main flow. The material is transported by the upward motion of the belt, where the material flow is split by one stream split into two streams. These material streams are mixed and mixed at the end of the conveyor by an auger mixing system before leaving the main conveyor.

This unique arrangement evens out the temperatures in the mix and blends large and small stones. The result is consistent and long-lasting road quality, according to the manufacturer.

Smart belt conveyor design reducing total operating costs

The rubber feeder belt is mounted directly on metal stiffeners. This allows longer intervals for belt changes and greater reliability reducing total operating costs.

For longer uptime, the rubber belt connection has been optimized and extensive testing under varying conditions with various compounds has verified improved stability. Additionally, the newly positioned spray beam under the front hopper flap ensures a permanent wet feed strip. This prevents adhesion with difficult mixtures and weather conditions, according to the manufacturer.

The in-feed belt is held in place by rollers of chain, so no chain has to be dismantled when changing belts. The new strap is attached to the old with a quick-attach system and fed into place. This design allows a feed belt change in a few hours. In addition, no vulcanization is necessary, as the tape is immediately ready for use.

The Dynapac MF2500CS can be used to transfer a variety of materials such as asphalt, RCC, aggregates or sand. Thanks to the precise belt control and the collapsible material hopper, as well as the optional rubber skirt, the transported material can be fed precisely.

For large paving widths, the Dynapac MF2500 offers a feed capacity of up to 4,000 tonnes per hour.

The Dynapac charger also offers a cleaning time of less than 30 minutes. Optimized cleaning concept with three separate pumps, enlarged release agent hose and hose connections at the front and rear of the metering device prevent material from sticking to the metering device, minimizing cleaning at the end of the job daytime.

Operator comfort

The MF2500CS MTV’s hydraulic lifting platform raises the operator’s area approximately 4 feet with the push of a button providing a full 360 degree view of the jobsite.

The Truck Assist feature makes docking/unhooking the truck to the feeder simple and efficient and eliminates jobsite dumping. Plus, a series of LED light bars signal the truck driver when to back up, dump material and when to drive away. The light sequences are controlled by the feeder operator.

The dashboard of the MF2500CS features a large 7-inch screen. screen that displays vital parameters of the charger. Three well positioned cameras allow the operator to view the front and rear of the feeder and the paver hopper area always providing optimum visibility around the feeder.

Investment flexibility

The MF2500CS can be fitted with the SW6500 SwingApp Conveyor for long side reach for paving over barriers and in-line or step paving applications. Dynapac MF2500CS is the only machine that offers this flexibility to add the Swing application at the time of initial purchase or at a later date, the manufacturer said.

The new 28 foot long SW6500 conveyor has a side reach of 12.5 feet. With its integrated quick-coupling cylinders and lifting points, the SW6500 can be mounted behind any MF2500CS in 20 minutes. This reduces investment costs for contractors using a single Swing application for multiple machines in their fleet. The system reduces wear and makes the MF2500CS a more flexible machine.

Remote Support

Maintaining a safe distance between the material loader and the paver – while simultaneously docking the truck to the loader and the paver – can be a daunting task. Dynapac Distance Assist automatically maintains a set distance between the paver and the feeder. The loader is equipped with a laser sensor, which allows the loader operator to virtually connect to the paver and track the speed of the paver’s movement.

The feeder operator can concentrate on the task at hand, which is material transfer. Combined with the ability to gain multiple distances, feeding two pavers becomes less stressful with the Dynapac MF2500CS equipped with the SwingApp. To inform the paver operator, the feeder is equipped with an LED bar which indicates the status of the radar sensor and the deviation from the correct distance.

Swing aid

Feeding two pavers at the same time is often demanding for the feeder operator. Via the SwingApp, Dynapac Swing Assist assists the operator by recording swing height and angle for the locations of both pavers, allowing the operator to recall positions at the touch of a button.

In combination with Distance Assist, the conveyor automatically moves to the correct position and SwingApp moves directly above the paver hopper.

For more information, visit www.dynapac.us.

Comments are closed.