Komatsu Smart Construction dashboard is now a reality

[ad_1]

You probably got a glimpse of it at ConExpo 2020. It is now a reality. Komatsu has just announced the availability of its Smart Construction dashboard to enable the digital transformation of its customers’ sites.

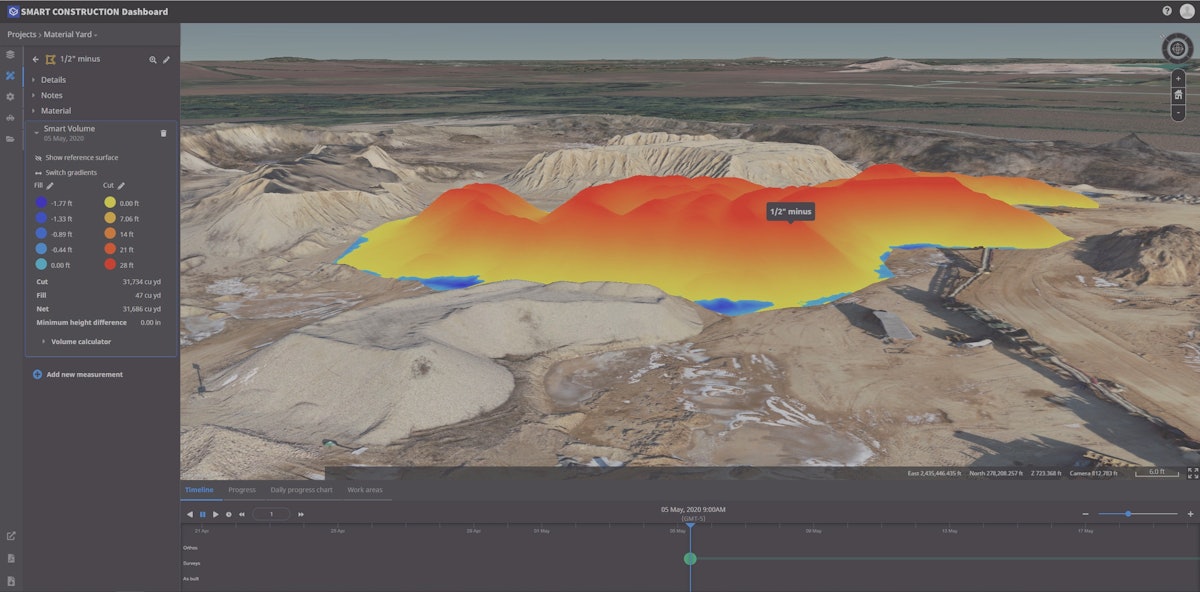

The dashboard combines data from multiple sources to create a complete picture of the work being done on an earthworks site. It is basically a mapping tool that uses data from drones and GPS machines to measure cut / fill, quantities and productivity and show you these results in 3D, near real time.

With the dashboard, you can confirm that your pre-bid topographic map is correct, monitor site progress, document site conditions and proof of change orders, and measure stock quantities. A reading function in the timeline function allows you to review work done in previous days or weeks. Site-wide visuals, cross sections and individual measurements are also available through the dashboard tools.

“In a typical scenario, they fly the drone in the morning and come back to the office to upload the data to the dashboard,†says Yoetzin Diaz, Smart Construction Solutions Manager at Komatsu. “Once they have their drone flight data, they can start creating measurements, whether it’s yesterday’s stock or a fill map of the entire job site.”

Diaz, who worked for a general contractor before coming to Komatsu, explains that contractors often don’t have the software to assess daily and weekly production progress. With the Komatsu Smart Construction dashboard, they can determine productivity and make decisions for subsequent deployment of operators, trucks and machines in minutes.

“I see a lot of entrepreneurs taking pictures and tiling them to get the big picture, and it takes a long time. It’s a lot of work; it is not very efficient even after getting all the photos. With a drone and the Smart Construction dashboard, you could have that in an hour or less. It’s accessible, practical and collaborative, â€she says.

The dashboard can be used in all phases of construction: pre-planning, monitoring progress or even after construction. “When your project is done, you can go back and look at all the work that has happened and use it as such to submit it for payment. So you have a one-stop-shop for all of this.

Because the information is digital and web-based, it can be shared with subcontractors, general contractors or owners who also need to see how the work is progressing, she says.

The Smart Construction dashboard is powered by Cesium, a platform used to visualize, analyze and share 3D data. Cesium’s 3D visualization engine combines video game infographic technology with GPS precision that links data to its precise location on the globe. Komatsu’s system for the dashboard uses DJI drones, but drones from other manufacturers will work as long as they are equipped for photogrammetry and have the correct software and file format, Diaz explains.

When presented at ConExpo, the dashboard and drone were just two of 11 smart construction tools featured by Komatsu. And while the Smart Construction dashboard is used today as a productivity mapping and tracking tool, other Komatsu Smart Construction features can potentially be added or integrated into it, Diaz explains.

To learn more about the full suite of Komatsu Smart Construction tools, see our Komatsu video at ConExpo 2020 here.

[ad_2]